How Premier Aluminum Llc can Save You Time, Stress, and Money.

Table of ContentsGetting My Premier Aluminum Llc To WorkUnknown Facts About Premier Aluminum LlcWhat Does Premier Aluminum Llc Mean?Getting My Premier Aluminum Llc To Work

(https://myspace.com/premieraluminum)Making use of low price and unqualified suppliers can cause top quality problems, and lost time and cash in the long run. To assist you via the process, below are some things to think about when picking the appropriate steel spreading provider.

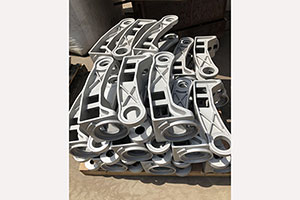

As an example, a company that only utilizes the financial investment casting process will attempt to market you on why that process is best for your application. However what happens if using the sand spreading process is best for you and your requirements? Rather, look for a supplier that supplies a variety of casting procedures so the ideal choice for YOU is selected

If collaborating with a single source for all of your casting needs is crucial to you, the provider needs to be diverse in its capacities. When integrated with other incorporated capacities, this can aid streamline and press the supply base. When picking the ideal casting distributor, careful consideration should be given to top quality, solution, and price.

Things about Premier Aluminum Llc

Purchasers increasingly select casting distributors that have machining abilities. If the spreading supplier uncovers an issue throughout machining, the issue is resolved quicker with no disagreement over whose mistake it is.

Problem or no, integrated machining simplifies the supply chain and lowers dealing with time and shipping cost before the item makes it to the consumer. What do you require from your casting distributor? Are you searching for somebody to just provide a metal component to your doorstep or do you need why not try this out a lot more? If you do not have internal metallurgy know-how, confirm that the supplier can supply guidance in picking the proper alloy based on your details application.

Some foundries are minimal or specialized. Make sure the supplier can fulfill all your material or alloy demands to get rid of the need for several providers.

The Facts About Premier Aluminum Llc Uncovered

Study the vendor's site. Talk to a sales representative or service associate. Ask a whole lot of questions. Visit their facility. Get an understanding of what they can do for you and if you can see on your own developing a solid, mutual connection with them.

Aluminum is likewise lightweight and has good deterioration resistance, making it ideal for applications where weight and toughness are necessary variables. In addition, light weight aluminum spreading is a cost-efficient approach of manufacturing, as it needs less power and sources than other methods. Iron spreading, on the various other hand, involves putting molten iron right into a mold to develop a preferred form.

Premier Aluminum Llc Fundamentals Explained

Iron spreading is likewise able to withstand high temperature levels, making it ideal for usage in applications such as engine components and industrial equipment. Iron spreading can be more expensive than aluminum casting due to the greater price of raw materials and the energy needed to melt the iron. When making a decision between aluminum spreading and iron spreading, it is very important to consider the particular needs of the application.

In final thought, both aluminum casting and iron casting have their own special benefits and drawbacks. There are three sub-processes that fall under the group of die spreading: gravity die casting (or permanent mold casting), low-pressure die casting and high-pressure die casting. To get to the completed product, there are 3 primary alloys used as die spreading product to select from: zinc, aluminum and magnesium.